Product Details

Natural Gas Operated Pumps are CSA (Canadian Standards Association) certified to ANSI LC6 standard for operation using sweet or sour natural gas. The gas pump utilizes Aluminum or 316 Stainless Steel wetted construction with Nitrile or Virgin PTFE diaphragms and check balls. The gas valve is constructed of Aluminum with Nitrile or FKM (fluorocarbon) elastomers. Pumps are fully groundable, preventing static discharge. A Stainless Steel gas valve option is available on G15 to G30 pumps for more corrosive applications.

Highlights

- Safely powered by compressed air or natural gas depending on the application. Dual Power capabilities offers simplified purchasing, maintenance and training while reducing inventory.

- Elastomeric seals are compatible with the various chemicals normally expected to be found in both sweet and sour gas.

- Every pump is leak factory tested to 150 PSI to ensure natural gas emission are properly contained.

- Complies with NACE Standard MR0175/ISO15156 for corrosion resistance.

- Constructed to prevent accumulation of static electric charge and fully groundable to ensure static electricity dissipation (comes standard with attached grounding strap).

- Hydrostatic strength tested pressure to 500 PSI (five times the maximum operating pressure, the highest standard in the industry).

- Canadian Technical Letter R-14 requires 500 PSI

- ANSI LC6 requires 400 PSI

- Hydraulic Institute requires 188 PSI

| SPECIFICATIONS | G-Series |

|---|---|

| Type | Pneumatically Operated |

| Fluid Suction & Discharge Connection | 1/2 – 3″ |

| Maximum Operating Pressure | 100 PSI (689 kPa) |

| Maximum Flow Rate Per Minute | 15 – 235 Gallons 56 – 889 Litres |

| Maximum Head | 231 ft. of water (100 PSI) |

| Maximum Displacement Per Stroke | 0.026 – 0.94 Gallons 0.098 – 3.56 Litres |

| Maximum Suction Lift | 24 ft. (7 m) |

| Maximum Solids Handling | 0.125 – 0.38” 3 – 9.65 mm |

- Salt Water Transfer / Disposal

- Tank Bottoms Circulations

- Utility Service for Spill Clean-Up

- General Fluid Transfer

- Surface Casing Grout and Cellar Pump Out

- Sump Pumping

- Hot Glycol Circulation as Heat Trace for Well Site Applications

- Diesel Fuel Transfer

- General Duty Spill Cleanup

- Sea Water Pump for Drilling Mud Make Up

- Produced Water / Condensate Transfer

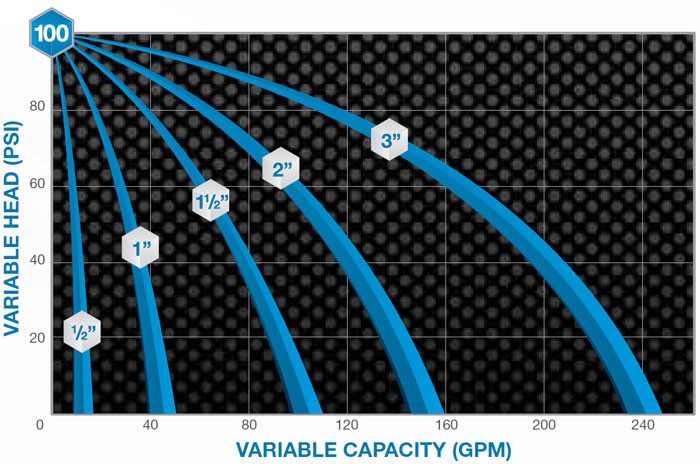

G-Series Pumps Quick Reference Chart

| Model # | Intake/Discharge Pipe Size | Capacity |

|---|---|---|

| G05 | ½” NPT | 0 – 15 Gallons / Minute 0 – 56 Litres / Minute |

| G1F | 1” NPT | 0 – 45 Gallons / Minute 0 – 170 Litres / Minute |

| G15 | 1 ½” NPT | 0 – 106 Gallons / Minute 0 – 401 Litres / Minute |

| G20 | 2” NPT | 0 – 150 Gallons / Minute 0 – 567 Litres / Minute |

| G30 | 3” NPT | 0 – 235 Gallons / Minute 0 – 889 Litres / Minute |

Why Buy a Natural Gas Operated Pump?

As the search for Oil and Gas moves into more remote locations around the world, the industry is continuously looking at more efficient and safe methods to drill for and produce these fluids. One such method is the use of produced natural gas to drive air operated double diaphragm (AODD) pumps for a variety of fluid transfer applications. Electricity is not available, in many remote locations, to drive a pump; therefore the use of natural gas is a necessity.

These applications have grown substantially, and numerous AODD pumps, designed for use with air only, are sold every year into applications where natural gas is used to drive the pumps instead of air.

The primary danger inherent in this application is the potential for static electricity build up due to material and product movement. The release of a static discharge in these applications could lead to a sparking which, in turn, could lead to a flash fire and possible explosion.

The G-Series Natural Gas Operated Pumps are designed, built, and are CSA (Canadian Standards Association) approved. The CSA specification sets standards to prevent static electricity accumulation as well as standards for burst pressure; heat resistance, leakage and upper and lower temperature operation. These fully ground-able pumps are constructed of materials compatible with both sweet and sour natural gas.

They are the first gas pumps built and certified to CSA (Canadian Standards Association) specifications 2.01 US and ATEX, in addition to being built to NACE MR1075 / ISO15156 standards.

Materials Profile

BUNA-N

General purpose, oil-resistant. Shows good solvent, oil, water, and hydraulic fluid resistance. Should NOT be used with highly polar solvents like acetone, and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons. Operating Temperature: -10 to 190 °F (-23 to 88 °C)

TEFLON (VIRGIN PTFE)

Chemically inert, virtually impervious. Very few chemicals are known to chemically react with PTFE; molten alkali metals, turbulent liquid or gaseous fluorine and a few fluoro-chemicals such as chlorine trifluoride or oxygen difluoride which readily liberate free fluorine at elevated temperatures. Operating Temperatures: -35 to 220 °F (-37 to 104 °C)